Shaped Pouch Production on bag making machine

Bag forming, die cutting process is shaped bag molding operation, there are two key point during production: sealing knife and die cutting.

1. Sealing knife design

Sealing knife position to be accurate, to match bag printing pattern, and reserve the right position and size for nozzle. If the position for nozzle is too large, the seal is not easy to sealing firmly, to have leak problem; if too small, it is difficult to be loaded nozzle. Generally, we suggest to reserve the position size according to girth of nozzle. Please re-check and polish sealing mold if sealing of shaped pouch is poor.

2. Die cutting

① Die cutting in-line with bag making machine

The advantage for in-line die cutting is save time, economical, sealing firm and even to avoid leaking problem. But the problem is not so easy for adjustment.

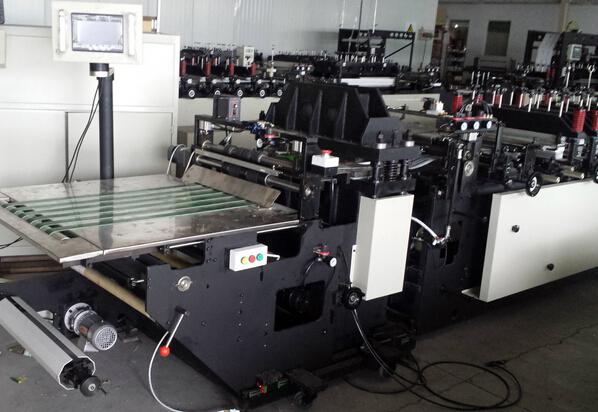

Die cutting unit in-line with bag making machine

② Separate die cutting machine

The advantages are high quality of molding shaped bag, little flash, also forming a plurality of shaped bags at one time. The disadvantages are: high production cost of the mold, a special bag may need to use several molds, low efficiency, take more time.