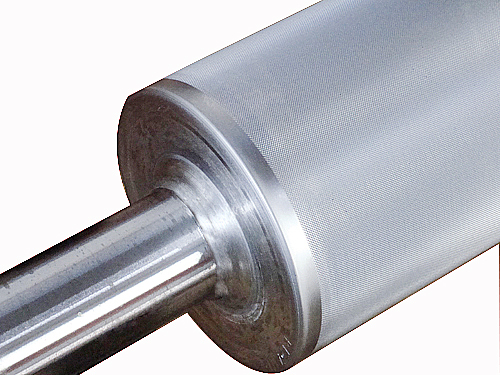

Project Description

It is modernized way that we used ultrasonic to clean anilox roller of printing machine, laminating machine. It works like this:to use the transducer converts electrical signals into mechanical vibration into the cleaning liquid. When the ultrasonic wave propagation in the liquid, cleaning liquid molecules are subjected to compression and expansion, and mechanical forces produced by liquid molecules constantly hit against the workpiece, then to clean it.

Featrues:

1.Washing liquid:water base+ little additive. Low cost,easy washing.

2.Imported thick Stainless steel material is acid proof, nice looking and long using life.

3.Automatic constant temperature system, 30 -80 ℃ can be adjusted.

4.Split-type structure, easy maintenance,long use.

5.Material of internal groove: imported Stainless steel

6.Material of cover and shell: Stainless steel

7.Not included in poaching of anilox roller.

Main Parameters:

| Model | 200 | 450 | 800 | 1300 |

| (Single groove) | (double groove) | (Single groove) | (Single groove) | |

| Vibrator QTY | 6 | 26 | 25 | 36 |

| Ultrasonic power | 300W | 1500W | 1500W | 2000W |

| Ultrasonic frequence | 40(KHz) | 40(KHz) | 40(KHz) | 40(KHz) |

| Heating power | 1000W | 1000W | 1000W | 2000W |

| Size of internal groove | 455*180*150mm | 630*300*160mm | 980*200*180mm | 1500*200*180mm |

Recent Works

- Cotton Buds Swabs Making Packing Machineadmin2017-02-24T10:52:40+00:00

Cotton Buds Swabs Making Packing Machine